Home / Technology

🔬 Core Technology: Binary Ionization Technology® (BIT™) + Ionized Hydrogen Peroxide (iHP™)

Across sectors, SG Environmental Solutions leverages SteraMist for tailored disinfection programs:

SG Environmental Solutions Pte Ltd deploys this technology to provide customized decontamination protocols across verticals such as:

They select among the SteraPak, Surface Unit, or Environment System based on size of space, contamination level, equipment sensitivity, and dwell-time/production needs—supplemented with managed on-site service and digital compliance reporting.

SG Environmental Solutions leverages TOMI’s SteraMist BIT™ and iHP™ systems for flexible, scalable, and high-efficacy decontamination across healthcare, food safety, commercial, institutional, and specialized environments. They combine portable and full-room fogging systems with managed services, ensuring fast cycle times (<15 min), digital validation, and residue-free safety using eco-friendly hydrogen peroxide mist technology.

SG Environmental Solutions uses Steramist’s patented ionized Hydrogen Peroxide (iHP)

technology combined with Binary Ionization Technology® (BIT)—a breakthrough solution

trusted by hospitals, research labs, and government agencies worldwide.

iHP Technology (Ionized Hydrogen Peroxide):

Environment System Fogging:

8-Step Disinfection & Decontamination Workflow

Customized disinfection plan based on site risk profile, layout, and usage.

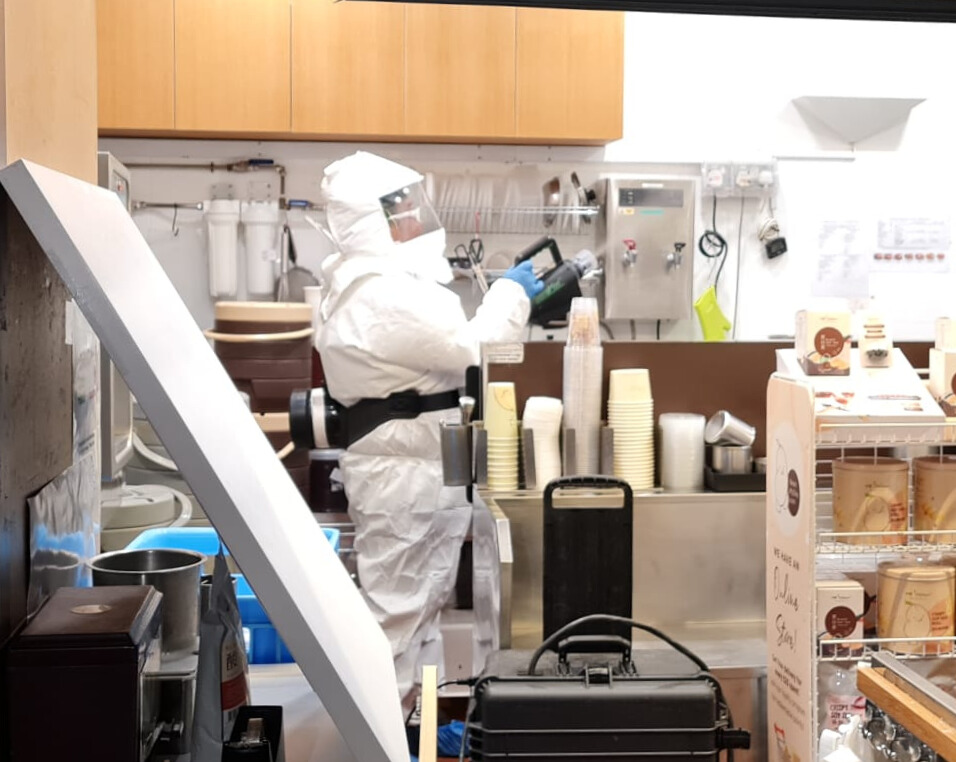

Pre-cleaning, PPE usage, room sealing (if needed), HVAC coordination.

Deploy Chemical Indicators (CI) and Biological Indicators (BI) to validate treatment efficacy.

Fogging or surface misting with ionized BIT® mist using cold plasma nozzles.

7–15 minutes for room fogging, approximately 5 seconds per square foot plus 7 minutes dwell time for surfaces.

Ensure hydrogen peroxide concentration is 1 ppm or less for safe re-entry.

Color-changing CI strips and BI spore testing to confirm 6-log pathogen kill.

Full validation report issued with test results, photos, and compliance notes.

A decontamination and infectious disease control company, provides environmental solutions for surface and air decontamination/sterilisation.

ISO45001 Health and Safety Management, ISO14001 Environmental Management and ISO9001 Quality Management Certified as well as BizSafe Star certified.